In my ongoing experiment in finding a good design for a quick-connect exercise wheel, I landed on a neat one. The concept has been in my mind for some time but it is really difficult and demotivating trying to find cheap off-the-shelf items to use. You have to get really creative and just play with things at the hardware store while everybody looks on wondering how nuts you must be to look at a pvc fitting for hours. It's not like I have catalogs of plastic fittings lying around after all.

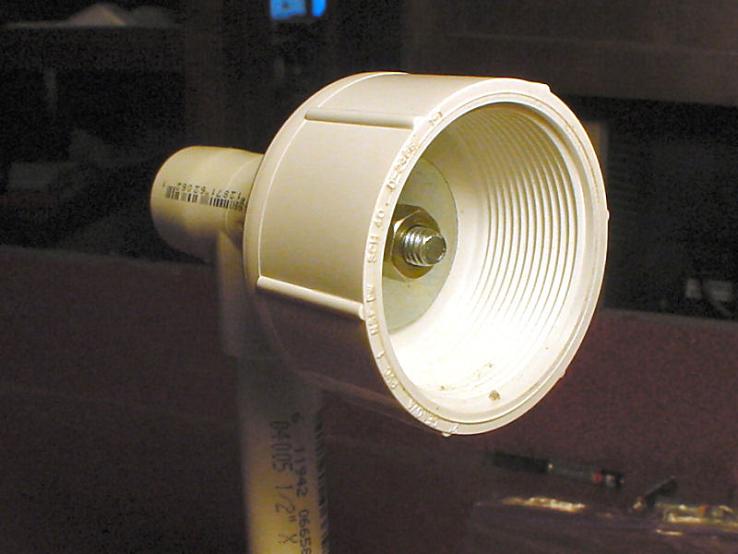

This new design uses a flat 2 inch threaded cleanout cover and a 2" threaded outside cap. The wheel itself becomes the nut which you rotate onto the threaded hub. Being plastic fittings, they are designed to seal, so they are very friction oriented and therefore hold the wheel firmly with no risk of detachment. You just grab the hub on the back of the wheel and either turn that, turn the wheel, or turn both until it disconnects.

The only thing left to do on this design concept is to create a tail guard to cover the area over the axle that rotates. This is really easy as you can see in previous designs but I am still trying to find a solution for this that takes up less depth.

Since my focus has been on the bearing and axle assemblies, I have been experimenting with original broken and actively used parts and wheels, so there are stray unrelated holes in these photos as well as things I should have cleaned up first...